1 Introduction [link id=”nnz7g”]

Many tunnels in the Netherlands need to be renovated in the coming years in order to keep them safe. Many tunnels also need to be adapted and smartly maintained to meet changing requirements. The required maintenance and renovation tasks raise all kinds of questions. The COB network seeks to jointly develop, combine and utilise knowledge. This includes knowledge of both organisational and technical aspects. This digital living document bundles this knowledge. Names of all persons involved can be found in Appendix 1: Participants.

This living document is an important source of knowledge for the renovation of tunnels. Many aspects are reflected in working groups of the COB tunnel programme. Throughout the document you will find links to relevant knowledge and current working groups.

Objective of this living document

The living document aims to inspire all professionals involved in tunnel renovation to come up with new ideas and solutions. This applies not only to making use of the experiences of previous renovation projects, but also to putting ‘learning’ on their agenda and sharing experiences and acquired knowledge with other projects. In this way, every project can benefit from lessons learned and add new lessons/chapters to this document. In this way, the document grows, the knowledge grows, and every renovation project gets a little better.

Although this living document contains much useful knowledge, it is not a renovation manual. Each tunnel project is unique and requires specific solutions. In this living document, methods and solutions are presented that have worked in certain situations, but that may not produce the desired result in other places or under different circumstances. Besides methods or solutions, this document also contains the questions, doubts and uncertainties that occupied and continue to occupy the authors. The motto for readers and users is therefore: always think critically!

Examples

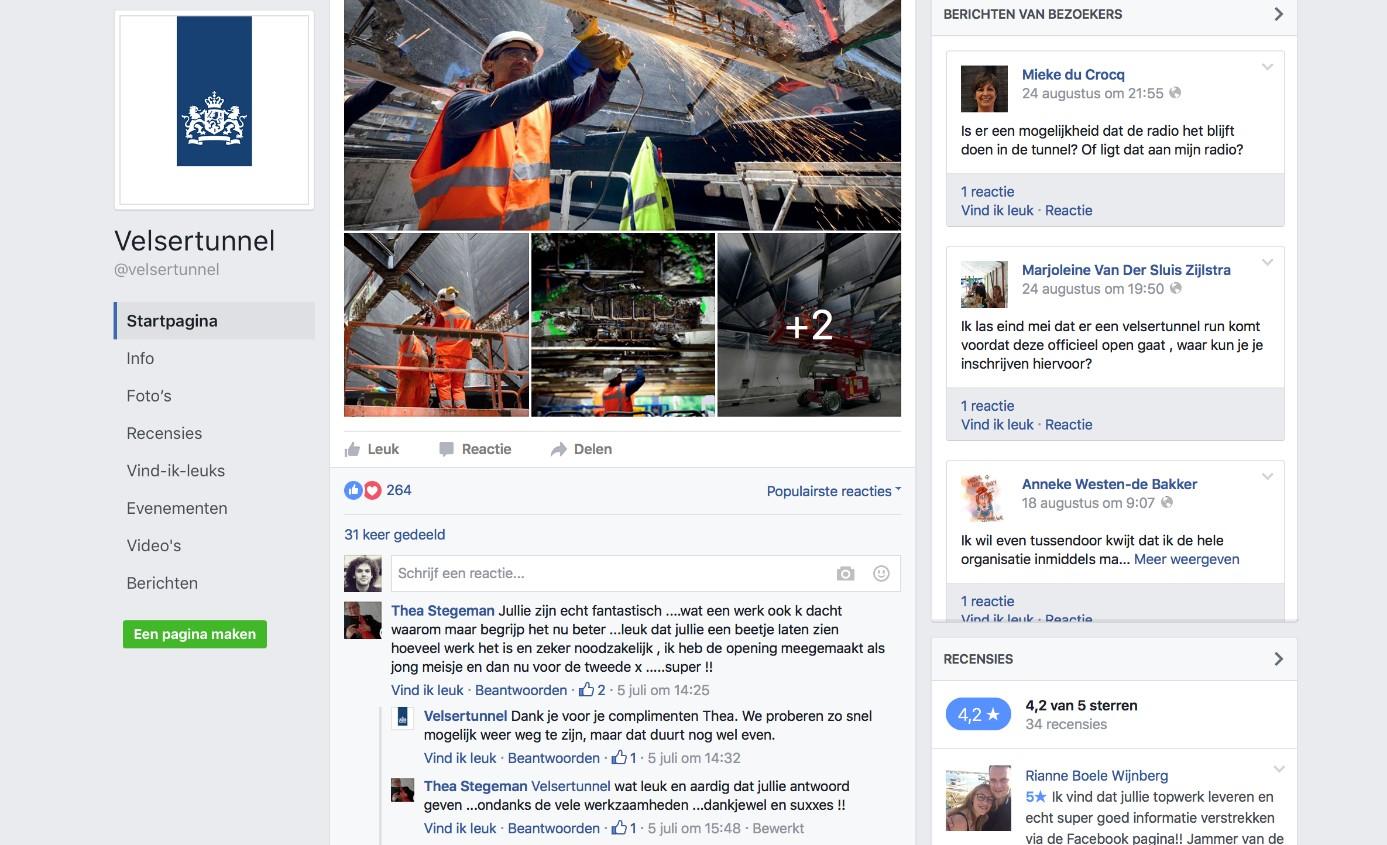

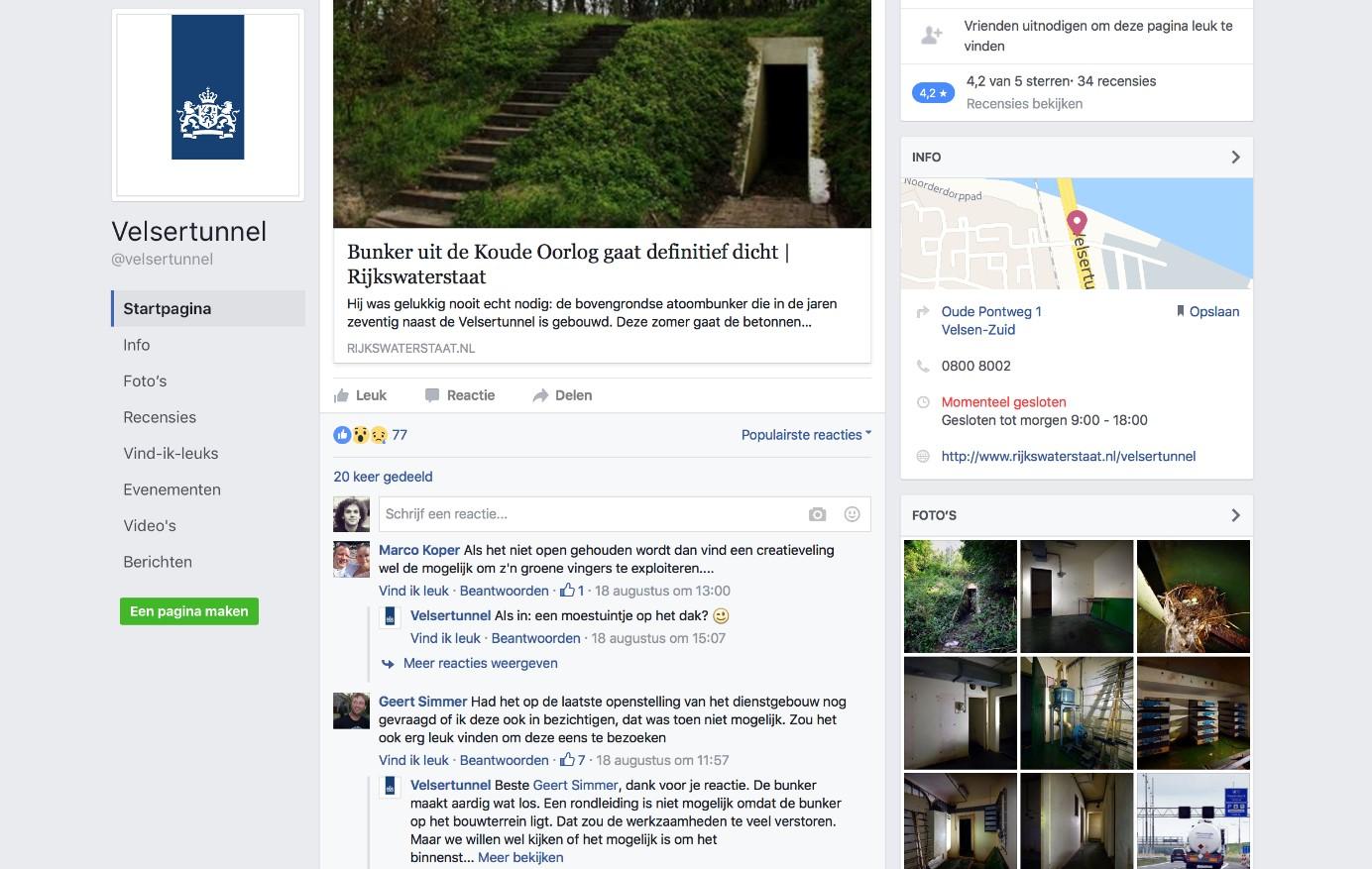

The first version of part 1 of this living document was drawn up in 2016 by a COB expert team in collaboration with experts from the Velsertunnel Project. This project is often cited as an example in popup boxes, as well as experiences from other tunnel (renovation) projects. More extensive experiences are included in the appendices.

Growing the living document

This document is called a ‘living document’ because it is a document that can easily be expanded with new experiences and new knowledge gained and developed in tunnel renovation projects. Already this living document has been updated and supplemented with numerous new practical experiences.

Do you see something that you think is wrong, or do you have a good example of a practical situation that can be added? Please let us know! You contact us at info@cob.nl / +31 85 4862 410.

Reading guide

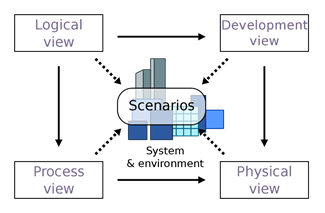

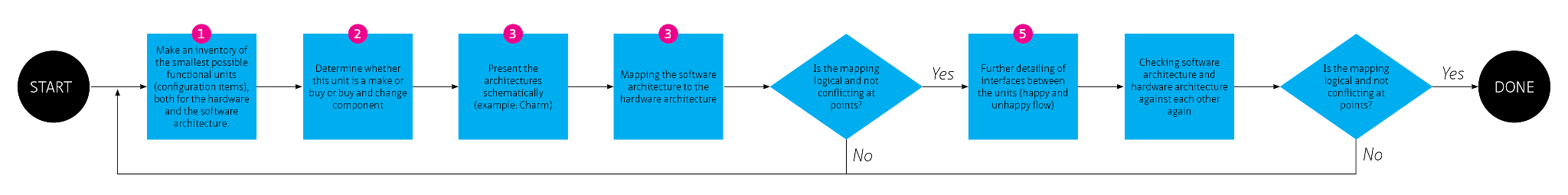

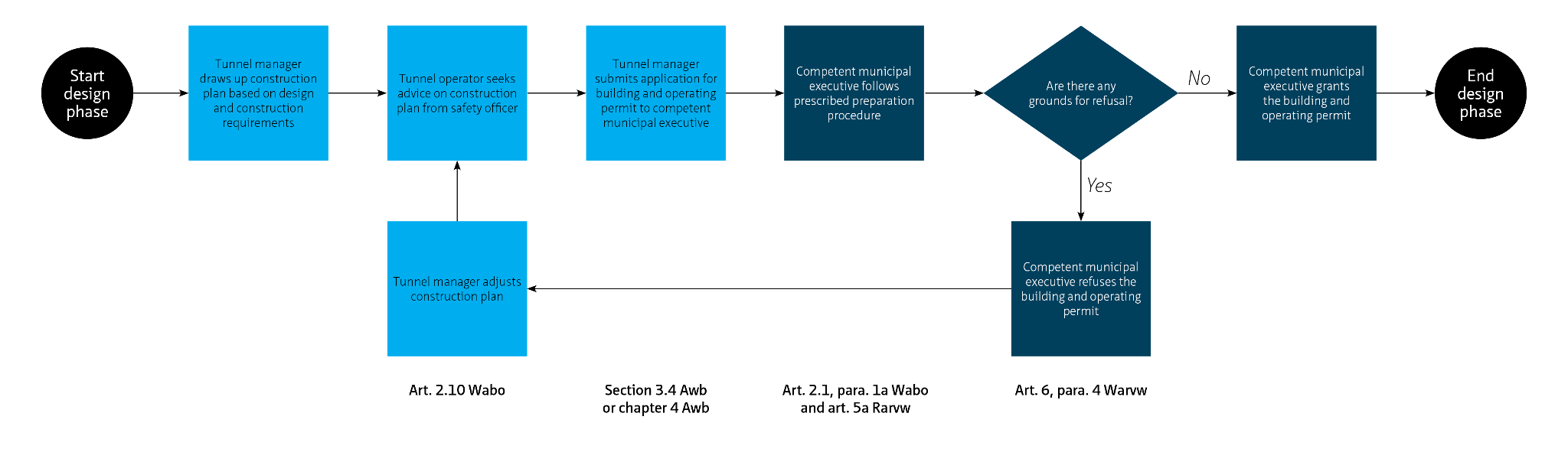

The first five chapters of this living document contain basic information about tunnel renovations. Chapters 6 to 14 deal with all kinds of specific matters that are important for renovation projects, such as the preparation, the system architecture, the main tunnel technical installations and, for example, logistics management and the licensing process.

The appendices contain relevant background information, but we recommend that you especially look at the COB knowledge products and projects that are referenced. That is the most up-to-date and in-depth knowledge.

Introduction workshop ‘Learn to renovate’

Would you like an introduction to tunnel renovation and the most important lessons from this living document, so that you and your team can start with a comparable level of knowledge? Please contact COB via info@cob.nl to discuss whether the one-day training is useful for your organisation.